Jacquemoux décolletage114 Rue du Nant, 74460 Marnazcommercial@jacquemoux.fr04 50 98 19 36Nous recrutons

Bar turning machining, CNC turning, multi-spindle, pins and precision turned parts - Jacquemoux Décolletage

To meet the requirements of our customers and market expectations, we have adapted our machinery to provide them with the best technical and economic solutions.

Our equipment allows us to meet demand for increasingly complex parts, while ensuring flexibility and responsiveness for small, medium and large series.

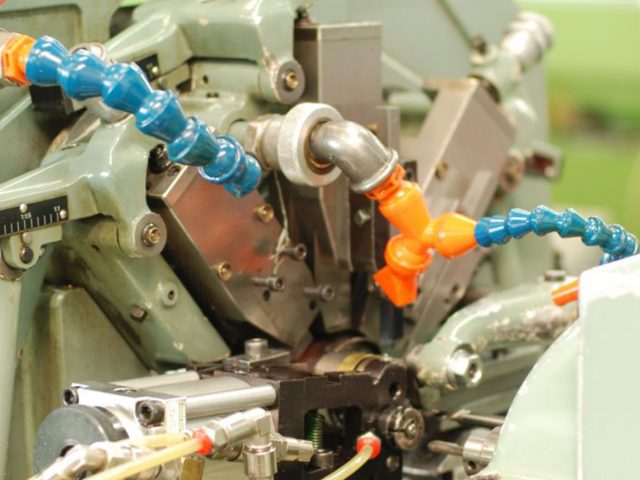

8 Multi-spindle lathes

Multi-spindle lathes machine several bars at the same time, from Ø 3 to 22 mm. These machines require relatively long adjustment times. They are mainly used to produce large and very large series of parts.

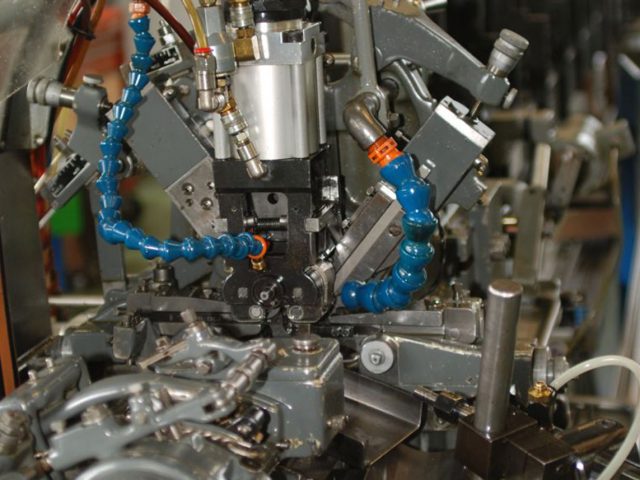

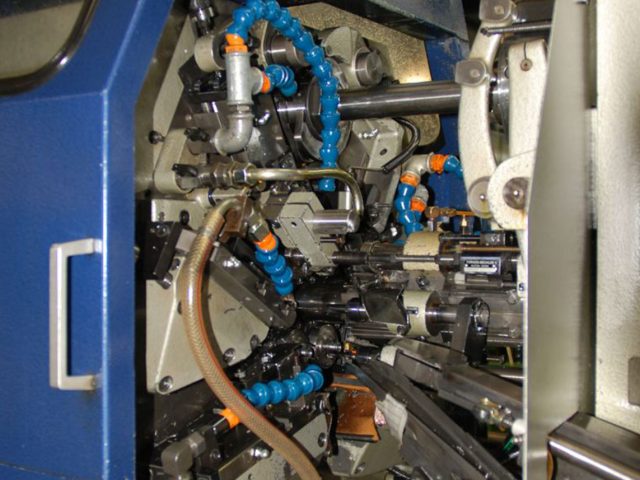

13 Computer controlled lathes

CNC lathes are used to produce precision turned parts without requiring subsequent reworking, such as milling, cross-drilling and various other operations.

Since the adjustment times of these machines are relatively quick, they are suitable for the production of small and medium series of turned parts with complex shapes. Machining from bars of Ø 4 to 65 mm and up to Ø 150 mm in billets.

Since the adjustment times of these machines are relatively quick, they are suitable for the production of small and medium series of turned parts with complex shapes. Machining from bars of Ø 4 to 65 mm and up to Ø 150 mm in billets.

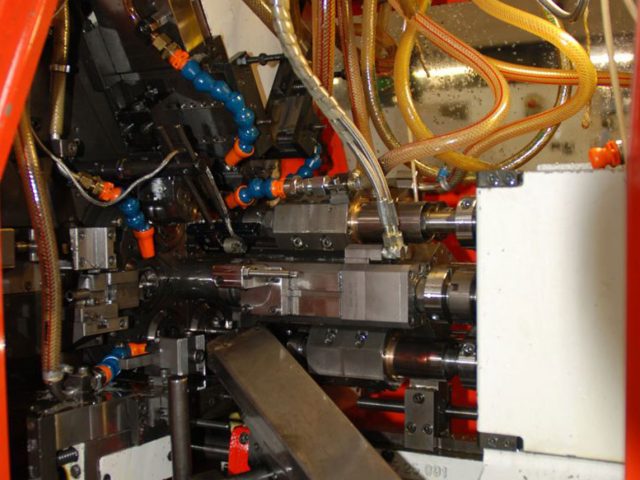

Transfer Machines – Rework and Grinding workshop

Our rework workshop is equipped with transfer machines for machining large series of complex parts. Other equipment is used to perform tapping operations, as well as milling, machining from billets and more. We also perform cylindrical grinding on centreless machines.

Washing and Cleaning

For washing and cleaning your parts, we have a centre for vacuum cleaning using modified alcohol. This innovative technology guarantees optimised cleaning and complies with the most demanding specifications of the arms industry, aeronautics industry, medical industry and others.

This innovative process that does not use chlorine products protects the health of our employees and the environment. It meets the challenges of sustainable development and the Grenelle de l’environnement

This innovative process that does not use chlorine products protects the health of our employees and the environment. It meets the challenges of sustainable development and the Grenelle de l’environnement